Hp tuners unlimited credits. HP Tuners complete '14 C7 Corvette tuning is available NOW. Seller doesn't have the Application Key or Sign In info for HP Tuners Website. You heard it here first.

Editor: McGraw Hill Professional

ISBN: 0071500944

Size: 19,44 MB

Format: PDF, Kindle

Read: 940

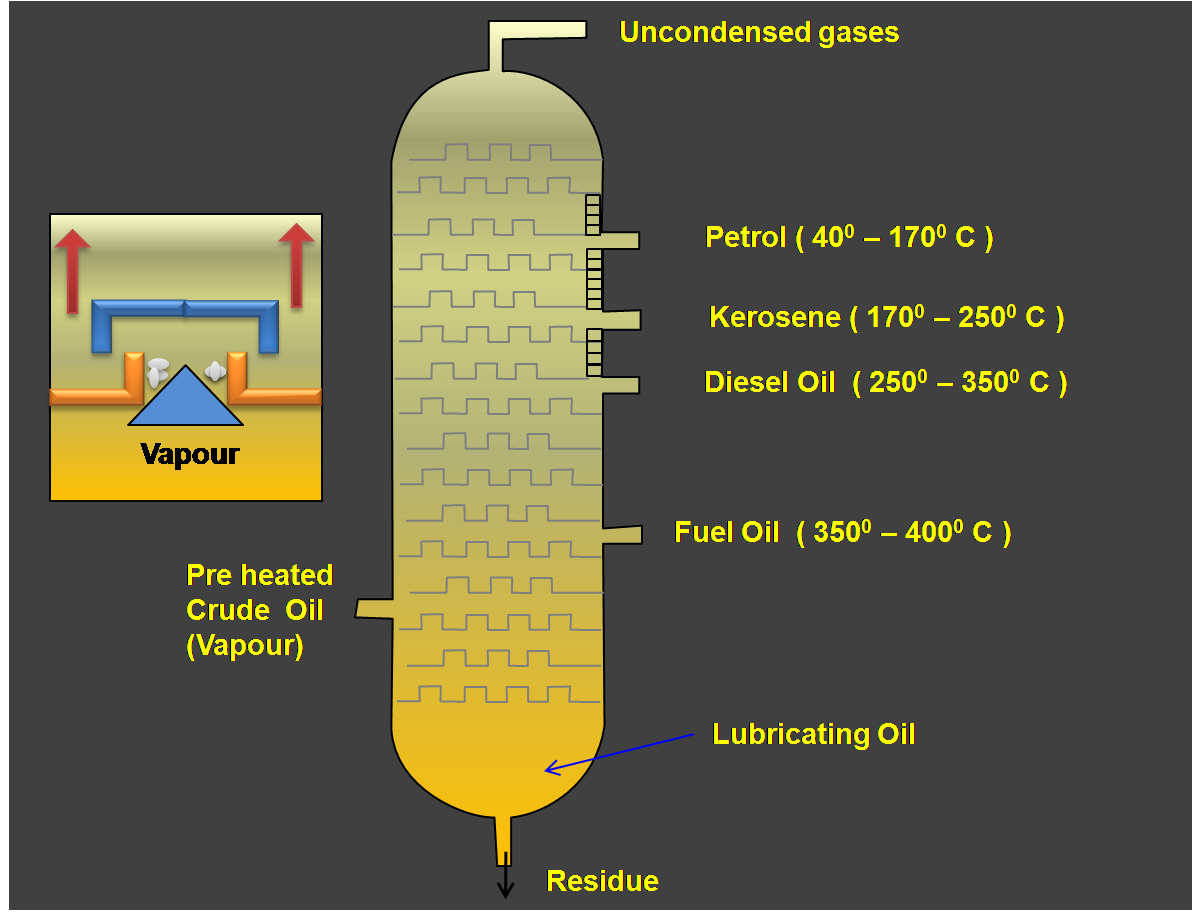

. Petroleum Industry Segments. Refinery Feedstocks. Refinery Products Part 2. Refining Processes. Refineries Part 3. Refinery Profitability. People. Hydrocarbon production maps If we are successfulyou will:. Gain insight into the basics of the refining process. Understand how a refinery makes desired products out.

Download* Offers detailed description of process chemistry and thermodynamics and product by-product specifications of plants * Contributors are drawn from the largest petroleum producers in the world, including Chevron, Mobil, Shell, Exxon, UOP, and Texaco * Covers the very latest technologies in the field of petroleum refining processes * Completely updated 3rd Edition features 50% all new material

Handbook Of Petroleum Processing

Editor: Springer Science & Business Media

ISBN: 1402028202

Size: 13,31 MB

Format: PDF

Read: 715

This handbook describes and discusses the features that make up the petroleum refining industry. It begins with a description of the crude oils and their nature, and continues with the saleable products from the refining processes, with a review of the environmental impact. There is a complete overview of the processes that make up the refinery with a brief history of those processes. It also describes design technique, operation, and, in the case of catalytic units, the chemistry of the reaction routes. These discussions are supported by calculation procedures and examples, sufficient to enable input to modern computer simulation packages.

Editor: McGraw-Hill Professional Publishing

ISBN: 9780070417960

Size: 17,24 MB

Format: PDF, ePub

Read: 106

Thoroughly revised and expanded, by 50%, the new edition of this handbook is a comprehensive guide to all aspects of petroleum refining processes. The author defines the technology, pollution control and economic aspects of 60 processes

Thoroughly revised and expanded, by 50%, the new edition of this handbook is a comprehensive guide to all aspects of petroleum refining processes. The author defines the technology, pollution control and economic aspects of 60 processesHandbook Of Petroleum Refining

Editor: CRC Press

ISBN: 1315356503

Size: 15,10 MB

Format: PDF, ePub, Docs

Read: 476

Petroleum refining involves refining crude petroleum as well as producing raw materials for the petrochemical industry. This book covers current refinery processes and process-types that are likely to come on-stream during the next three to five decades. The book includes (1) comparisons of conventional feedstocks with heavy oil, tar sand bitumen, and bio-feedstocks; (2) properties and refinability of the various feedstocks; (3) thermal processes versus hydroprocesses; and (4) the influence of refining on the environment.

Editor:

ISBN: 9781681173962

Size: 17,19 MB

Format: PDF, ePub

Read: 528

Fundamentals of Petroleum Refining present the fundamentals of thermodynamics and kinetics, and it explains the scientific background essential for understanding refinery operations. The text also provides a detailed introduction to refinery engineering topics, ranging from the basic principles and unit operations to overall refinery economics. The book covers important topics, such as clean fuels, gasification, biofuels, and environmental impact of refining. Petroleum refining is a unique and critical in the petroleum supply chain, from the wellhead to the pump. The other add value to petroleum mainly by moving and storing it (e.g., lifting crude oil to the surface; moving crude oil from oil fields to storage facilities and then to refineries; moving refined products from refinery to terminals and end-use locations, etc.). Refining adds value by converting crude oil (which in itself has little end-use value) into a range of refined products, including transportation fuels. The primary economic objective in refining is to maximize the value added in converting crude oil into finished products.

Handbook Of Petroleum Refining Processes Fourth Edition

Editor: McGraw Hill Professional

ISBN: 0071850503

Size: 19,45 MB

Format: PDF, ePub, Mobi

Read: 904

This fully revised resource presents the latest technologies and processes for petroleum refining from the world’s leading producers. Handbook of Petroleum Refining Processes has become a key reference in the chemical and petroleum engineering markets. The book is unique in that it presents licensable technologies for the refining of petroleum and production of environmentally acceptable fuels and petrochemical intermediates. The new edition covers the gamut of global refining technologies in light of recent changes to the sources of these fuels, as well as the most up-to-date global environmental regulations. Contributions come from such major licensors of petroleum refining technology as UOP, Inc., Shell, ExxonMobil Research and Engineering Company (EMRE), Chevron Lummus Global, Phillips 66, Belco, BP, and others. The new edition shifts its emphasis to accommodate the increased production of shale gas and shale oil which is changing the overall mix of hydrocarbon feeds. Declining conventional crude production and the need for regional energy independence continues to drive demand to use lower-cost, alternate feedstocks such as coal, shale oil, and heavy crude. To use alternate feedstocks in existing refineries, many processes need to be modified. The increase in diesel demand and stricter fuel specifications is driving refiners to look for ways to produce higher yields from existing assets. The book reflects these factors, plus the increase in residue conversion; hydrocracking evolving as a primary conversion process; and hydrotreating increasing as a way to treat virgin and cracked middle distillate streams. Offers detailed description of process chemistry and thermodynamics and product by-product specifications of plants Contributors are drawn from the largest petroleum producers in the world, including Chevron, Shell, ExxonMobil, and UOP Covers the very latest technologies in the field of petroleum refining processes and the shift toward shale gas and oil A complete listing and explanation of licensable global technologies for the refining of petroleum and the production of environmentally acceptable fuels and petrochemical intermediates Provides product-by-product specifications and process economics – capital investment annualized capital costs and the price range for each product

Editor: CRC Press

ISBN: 0203908643

Size: 13,85 MB

Format: PDF, ePub, Docs

Read: 574

This work highlights contemporary approaches to resource utilization and provides comprehensive coverage of technological advances in residuum conversion. It illustrates state-of-the-art engineering methods for the refinement of heavy oils, bitumen, and other high-sulphur feedstocks.

Refining Processes Handbook

Editor: Gulf Professional Publishing

ISBN: 9780750677219

Size: 20,22 MB

Format: PDF, ePub, Mobi

Read: 522

For the first time, an essential reference for the multi-billion dollar petrochemical industry that covers the complex topics involved in refining.

Editor:

ISBN:

Size: 20,57 MB

Format: PDF, Kindle

Read: 287

If staying on top of the latest developments in the petroleum refining process industry is part of your work; this one-stop resource delivers comprehensive coverage of how major players are taking these processes to new heights through technology. --

Petroleum Processing Handbook

Editor: CRC Press

ISBN: 9780824786816

Size: 15,70 MB

Format: PDF

Read: 995

A reference that details the pertinent chemical reactions and emphasizes the plant design and operations of petroleum processing procedures. The handbook is divided into four sections: products, refining, manufacturing processes, and treating processes. Wherever possible, shortcut methods of calcula

Secure Checkout

Personal information is secured with SSL technology.Free Shipping

Free global shippingNo minimum order.

Description

Fundamentals of Petroleum Refining presents the fundamentals of thermodynamics and kinetics, and it explains the scientific background essential for understanding refinery operations. The text also provides a detailed introduction to refinery engineering topics, ranging from the basic principles and unit operations to overall refinery economics.

The free Xerox Global Print Driver manages Xerox and non-Xerox printers on your network with a single, easy-to-use interface. It dramatically simplifies enterprise printer management for IT managers, making it easy to add and update printers without changing drivers. Get supplies and support for Phaser 4500. Although this product is no longer sold as new, please see our newer models. All Support and Drivers All Support and Drivers. All Support and Drivers All Support and Drivers. Register your product. Using Xerox® Genuine toner and ink in your Xerox printer will ensure that prints are delivered. Xerox phaser 4510 driver 64 bit.

The book covers important topics, such as clean fuels, gasification, biofuels, and environmental impact of refining, which are not commonly discussed in most refinery textbooks. Throughout the source, problem sets and examples are given to help the reader practice and apply the fundamental principles of refining. Brett aqualine em 100 manual download. Chapters 1-10 can be used as core materials for teaching undergraduate courses. The first two chapters present an introduction to the petroleum refining industry and then focus on feedstocks and products. Thermophysical properties of crude oils and petroleum fractions, including processes of atmospheric and vacuum distillations, are discussed in Chapters 3 and 4. Conversion processes, product blending, and alkylation are covered in chapters 5-10. The remaining chapters discuss hydrogen production, clean fuel production, refining economics and safety, acid gas treatment and removal, and methods for environmental and effluent treatments.

This source can serve both professionals and students (on undergraduate and graduate levels) of Chemical and Petroleum Engineering, Chemistry, and Chemical Technology. Beginners in the engineering field, specifically in the oil and gas industry, may also find this book invaluable.

- Provides balanced coverage of fundamental and operational topics

- Includes spreadsheets and process simulators for showing trends and simulation case studies

- Relates processing to planning and management to give an integrated picture of refining

Readership

Students in Chemical Engineering, practitioners in refineries, and consultants to the Oil and Gas industry

Preface

1. Introduction

1.1. Introduction

1.2. Refining Processes

1.2.1. Physical Separation Processes

1.2.2. Chemical Catalytic Conversion Processes

1.2.3. Thermal Chemical Conversion Processes

1.3. Refinery Configuration

1.3.1. Type of Products

1.3.2. Environmental Regulation

1.3.3. Crude Assay and Quality

1.3.4. Refinery-petrochemical Integration

1.3.5. Development of New Technology

2. Refinery Feedstocks and Products

2.1. Introduction

2.2. Composition of Crude Oils

2.2.1. Paraffins

2.2.2. Olefins

2.2.3. Naphthenes (cycloalkanes)

2.2.4. Aromatics

2.2.5. Sulphur Compounds

2.2.6. Oxygen Compounds

2.2.7. Nitrogen Compounds

2.2.8. Metallic Compounds

2.2.9. Asphaltenes and Resins

2.3. Products Composition

2.3.1. Liquefied Petroleum Gas (LPG)

2.3.2. Gasoline

2.3.3. Kerosene

2.3.4. Jet Fuel

2.3.5. Diesel Fuel

2.3.6. Fuel Oil

2.3.7. Residual Fuel Oil

2.3.8. Lube Oil

2.3.9. Asphalt

2.3.10. Petroleum Coke

2.4. Physical Property Characterization Data

2.4.1. Fractionation

2.4.2. True Boiling Point Distillation

2.4.3. ASTM Distillation

2.4.4. Simulated Distillation by Gas Chromatography

2.4.5. API Gravity

2.4.6. Pour Point

2.4.7. Viscosity

2.4.8. Refractive Index

2.4.9. Freezing Point

2.4.10. Aniline Point

2.4.11. Flash Point

2.4.12. Octane Number

2.4.13. Cetane Number

2.4.14. Smoke Point

2.4.15. Reid Vapour Pressure

2.4.16. Water, Salt and Sediment

2.4.17. Molecular Weight

2.5. Chemical Analysis Data

2.5.1. Elemental Analysis

2.5.2. Carbon Residue

2.5.3. Detailed Hydrocarbon Analysis

2.5.4. Hydrocarbon Family Analysis

2.5.5. Aromatic Carbon Content

2.5.6. SARA Analysis

3. Thermophysical Properties of Petroleum Fractions and Crude Oils

3.1. Introduction

3.2. Basic Input Data

3.2.1. Specific Gravity

3.2.2. Boiling Point Curves

3.2.3. ASTM Distillation

3.2.4. True Boiling Point Distillation

3.2.5. Conversion between ASTM and TBP Distillation

3.3. Pseudo-Components

3.3.1. Breakup of TBP Curve into Pseudo-components

3.3.2. Breakup of TBP Curve into Pseudo-components Using Generalized Form

3.3.3. Calculation of Pseudo-components Specific Gravities

3.4. Thermophysical Properties Calculation

3.4.1. Molecular Weight

3.4.2. Viscosity

3.4.3. Refractive Index

3.4.4. Molecular Type Composition of Petroleum Fractions

3.4.5. Pseudo-critical Constants and Acentric Factors

3.4.6. Generalized Equation for Thermophysical Properties

3.5. Calculation of Enthalpy of Petroleum Fractions

3.6. Estimation of Properties Related to Phase Changes

3.6.1. Cubic Equations of State

3.6.2. Vapour–liquid Equilibrium

3.7. Calculating Properties Utilizing UNISIM Software

Questions and Problems

4. Crude Distillation

4.1. Introduction

4.2. Process Description

4.3. Operation of Crude Distillation Units

4.3.1. Fractionation

4.3.2. Overflash

4.3.3. Column Pressure

4.3.4. Overhead Temperature

4.3.5. Pre-flash Columns and Crude Column Capacity

4.4. Crude Oil Desalting

4.4.1. Types of Salts in Crude Oil

4.4.2. Desalting Process

4.4.3. Description of Desalter

4.4.4. Desalter Operating Variables

4.5. Vacuum Distillation

4.5.1. Process Description

4.6. Crude Distillation Material Balance

4.6.1. Crude Assay Data

4.6.2. Material Balance

4.6.3. Sulphur Material Balance

4.7. Design of Crude Distillation Units Using Process Simulators

Questions and Problems

5. Catalytic Reforming and Isomerization

5.1. Introduction

5.2. Catalytic Reforming

5.2.1. Reformer Feed Characterization

5.2.2. Role of Reformer in the Refinery and Feed Preparation

5.2.3. Research Octane Number

5.2.4. Reforming Reactions

5.2.5. Thermodynamics of Reforming Reactions

5.2.6. Reaction Kinetics and Catalysts

5.2.7. Process Technology

5.2.8. Material Balance in Reforming

5.2.9. Process Simulation of Reformer by Equilibrium Reactions

5.3. Isomerization of Light Naphtha

5.3.1. Thermodynamics of Isomerization

5.3.2. Isomerization Reactions

5.3.3. Isomerization Catalysts

5.3.4. Isomerization Yields

Questions and Problems

6. Thermal Cracking and Coking

6.1. Introduction

6.2. Coke Formation

6.3. Thermodynamics of Coking of Light Hydrocarbons

6.4. Visbreaking

6.4.1. Feed Sources

6.4.2. Visbreaking Reactions

6.4.3. Visbreaking Severity

6.4.4. Kinetics of Visbreaking

6.4.5. Product Yield and Properties

6.4.6. Prediction of Visbreaking Yields

6.4.7. Process Description

6.5. Delayed Coking

6.5.1. Role of Delayed Coker

6.5.2. Process Description

6.5.3. Delayed Coking Variables

6.5.4. Types of Coke and their Properties

6.5.5. Coking and Decoking Operation

6.5.6. Delayed Coker Yield Prediction

6.5.7. Process Simulation of Delayed Coking

6.6. Fluid Coking

6.7. Flexicoking

6.7.1. Yield Correlations for Flexicoking

Questions and Problems

7. Hydroconversion

7.1. Introduction

7.2. Hydrotreating

7.2.1. Objectives of Hydrotreating

7.2.2. Role of Hydrotreating

7.2.3. Chemistry of Hydrotreating

7.2.4. Hydrotreating Catalysts

7.2.5. Thermodynamics of Hydrotreating

7.2.6. Reaction Kinetics

7.2.7. Hydrotreating Processes

7.2.8. Make-up Hydrogen

7.2.9. Operating Conditions

7.2.10. Hydrotreating Correlations

7.2.11. Simulation of ARDS Unit

7.3. Hydrocracking

7.3.1. Role of Hydrocracking in the Refinery

7.3.2. Feeds and Products

7.3.3. Hydrocracking Chemistry

7.3.4. Hydrocracking Catalysts

7.3.5. Thermodynamics and Kinetics of Hydrocracking

7.3.6. Hydrocracking Processes

7.3.7. Process Configuration

7.3.8. Hydrocracking Severity

7.3.9. Catalytic Dewaxing

7.3.10. Hydrocracking Correlations

7.3.11. Simulation of Hydrocracking Units

Question and Problems

8. Fluidised Catalytic Cracking

8.1. Introduction

8.2. Role of FCC in the Refinery

8.3. Feedstock and Products

8.4. Fluidisation

8.5. FCC Reactions

8.5.1. Primary Reactions

8.5.2. Secondary Reactions

8.6. Thermodynamics of FCC Reactions

8.7. FCC Catalyst

8.7.1. Zeolite

8.7.2. Matrix

8.8. FCC Configuration

8.9. Process Description

8.10. Modes of Fluidisation in FCC unit

8.11. FCC Yield Correlations

8.12. Material and Energy Balances

8.12.1. Material Balance

8.12.2. Energy Balance

8.13. Kinetic Model for FCC Reactor

8.14. Concentration and Temperature Profiles in the Riser

8.15. Simulation of FCC Unit

8.16. New Technology

8.16.1. Deep Catalytic Cracking

8.16.2. Catalytic Pyrolysis Process

8.16.3. Petro-FCC

Questions and Problems

9. Product Blending

9.1. Introduction

9.2. Reid Vapour Pressure Blending

9.3. Flash Point Blending

9.4. Pour Point Blending

9.5. Cloud Point Blending

9.6. Aniline Point Blending

9.7. Smoke Point Blending

9.8. Viscosity Blending

9.9. Gasoline Octane Number Blending

9.10. Linear Programming (LP) For Blending

Questions and Problems

10. Alkylation

10.1. Introduction

10.2. Role of Alkylation and Polymerization Units in the Refinery

10.3. Alkylation Processes

10.3.1. Sulphuric Acid Alkylation Process

10.3.2. Hydrofluoric Acid Alkylation

10.3.3. Solid Catalyst Alkylation

10.3.4. AlkyClean Process

10.4. Kinetics and Thermodynamics of Alkylation

10.4.1. Effect of Operating Conditions

10.5. Performance of Alkylation Process

10.6. Material Balance Calculations Using Yield Factors

10.7. Simulation of the Alkylation Process

Questions and Problems

11. Hydrogen Production

11.1. Introduction

11.2. Hydrogen Requirements in Modern Refineries

11.3. Steam Reforming

11.3.1. Flow Process

11.3.2. Feed Preparation

11.3.3. Steam Reforming Reactions

11.3.4. Thermodynamics of Steam Reforming

11.3.5. Operating Variables (Crew and Shumake, 2006)

11.3.6. Reformer Process Simulation

11.4. Product Purification

11.4.1. High-Temperature Shift Converter

11.4.2. Low-Temperature Shift Converter

11.4.3. Carbon Dioxide Removal

11.5. New Developments in Steam Reforming

Questions and Problems

12. Clean Fuels

12.1. Introduction

12.2. Specifications of Clean Fuels

12.3. Production of Clean Fuels from Crude Oil

12.3.1. Deep Desulphurization

12.4. Production of Clean Fuels from Natural Gas and Coal

12.4.1. Synthesis Gas Production

12.5. Production of Clean Fuels from Biological Sources (Biofuels)

12.5.1. Bio-diesel

12.5.2. Ethanol and Methanol

12.5.3. Bio-Fuel from Flash Pyrolysis

12.5.4. Bio-Fuel from Hydrothermal Upgrading (HTU)

12.5.5. Gasification Routes

Questions and Problems

13. Residue Upgrading

13.1. Introduction

13.2. Upgrading Options

13.3. Non-catalytic Residue Upgrading Processes

13.3.1. Solvent Deasphalting

13.3.2. Thermal Processes

13.4. Catalytic Processes

13.4.1. Residue-fluidized Catalytic Cracking

13.4.2. Hydroprocessing

13.4.3. Aquaconversion

Questions and Problems

14. Safety in Petroleum Refineries

14.1. Introduction

14.2. Hazards in Refinery Units

14.2.1. Crude Oil Pre-treatment

14.2.2. Crude Oil Distillation

14.2.3. Catalytic Reforming

14.2.4. Thermal Cracking

14.2.5. Hydrotreating and Hydrocracking

14.2.6. Fluid Catalytic Cracking

14.2.7. Alkylation

14.2.8. Hydrogen Production

14.3. Safety Programs and Regulations

14.4. Accidents and Loss Prevention Measures

14.5. Risk Management and Risk Assessment

14.6. Fire and Explosions

14.7. Hazard Analysis

14.7.1. Worst Case Scenario

14.7.2. Fault Tree Analysis

14.7.3. HAZOP Case study

14.8. Safety Considerations in Plant Layout

14.9. Safe Operation Systems

14.9.1. Pressure Relief Systems

14.9.2. Flare Relief System

14.9.3. Air Emission Monitoring

14.9.4. Water Emission Monitoring

14.9.5. Solid Waste Monitoring

14.10. Emergency Alarms

14.11. Noise in Refinery

Questions and Problems

15. Acid Gas Processing and Mercaptans Removal

15.1. Introduction

15.2. Absorption of Acid Gases

15.2.1. Chemical Solvents

15.2.2. Physical Solvents

15.2.3. Membrane Absorption

15.3. Sulphur Recovery

15.3.1. Claus Process

15.3.2. Tail Gas Clean Up

15.4. Mercaptans Removal

15.4.1. Gasoline MEROX

15.4.2. Kerosene MEROX

Question and Problems

16. Refinery Economics

16.1. Introduction

16.2. Refining Capacity

16.3. Refining Costs

16.3.1. Capital Costs

16.3.2. Operating Costs

16.3.3. Factors Affecting Refinery Costs

16.4. Refining Margins

16.5. Refinery Complexity

16.6. Economic Analysis

16.6.1. Cash Flow Diagram

16.6.2. Time Value of Money

16.6.3. Inflation

16.6.4. Taxation and After-tax Cash Flow

16.6.5. Profitability and Project Evaluation

16.6.6. Case Study: Refinery Economic Evaluation

16.7. Global Trends

Questions and Problems

17. Environmental Aspects in Refining

17.1. Introduction

17.2. Wastes in Refinery Units

17.2.1. Desalter

17.2.2. Crude Distillation

17.2.3. Catalytic Reforming and Isomerization

17.2.4. Thermal Cracking and Coking

17.2.5. Hydrocracking

17.2.6. Hydrotreating

17.2.7. Fluid Catalytic Cracking (FCC)

17.2.8. Alkylation

17.2.9. Asphalt Production, Solvent Extraction and Dewaxing

17.2.10. Hydrogen Production

17.3. Waste Management

17.3.1. Gas Waste

17.3.2. Wastewater

17.3.3. Solid Waste

Questions and Problems

18. Overall Refinery Case Study

18.1. Introduction

18.2. The Case Study

Appendices

Appendix A Conversion Factors

Appendix B Definition of Terms

Appendix C Process Simulator (UNISIM) Manual

Appendix D Research Octane Number for Hydrocarbons

Notation

Index

Mar 10, 2017 Download Bangla Islamic gazal mp3 songs. Admin (ছাদ্দাম) Tuesday, 21 March 2017. Download bangla Islamic gazal uploaded by saddam hussain of Narshingbari norshingbari sabdam hossen. Islamic gojol,gajhaol,gozzol 100+Islamic gazal. Banglaislamicgazal, BANGLA ISLAMIC SONG O-MODINAR -BULBULI I New Bangla Islami Naat 2016 I Kalarab Shilpigosthi Diu Je Amar Rokeya Parbhin Bangla Islamic Bangla Gazal Gojol 2019 GoBindas Bangla Geeti, Audeo Mp3 & HD MP4, 3Gp Video Download. Bangla islamic song download and best bangla islamic mp3 song collection website - mp3 islamic song full - new islamic song mp3 bangla gojol download. Bangla Islamic Song. Islamic Cultural Organization. Islamic Song Album. Islamic Song Artist. Female Artist. Islamic Nazrul Sangeet. Download Islamic Song Bangla Songs from eTunes. Stay away from piracy, purchase the Genuine copy of your favorite songs. Bangla islamic song 2018 mp3 download.

Details

- No. of pages:

- 516

- Language:

- English

- Copyright:

- © Elsevier Science 2010

- Published:

- 27th November 2009

- Imprint:

- Elsevier Science

- Hardcover ISBN:

- 9780444527851

- eBook ISBN:

- 9780080931562

Mohamed Fahim

Department of Chemical Engineering, College of Engineering and Petroleum, Kuwait Univerity, Safat, Kuwait

May 05, 2015 Bookworm Adventures Full PC Game Overview. Bookworm Adventures download free. full Game is a follow-up to the word-forming computer puzzle game Bookworm from PopCap Games. Released in November 2006, Bookworm Adventures combines the «create words from sets of letters» aspect of Bookworm with several elements of a role-playing video game. Bookworm game download full version. Bookworm Deluxe Game. The goal of Bookworm Deluxe is to make words to feed the hungry Bookworm, while watching out for burning letters that could ignite your library! In both game types, Classic and Action, you must create words by linking letters on the board together. To select a letter, just click on it. Bookworm download free. full Version. The game has two modes. «Classic» mode is untimed, while «Action» mode uses randomly appearing burning tiles to create a time-limited game. If the player clicks on game mascot Lex, found off to the side of the play area, all of the tiles will be scrambled; however, this will produce a rush of red tiles. Check Gaming Zone: Full Version Games Free Download, Download Full Version Games, Full Version Games Free Download, free. download full Version Games. Welcome To CheckGamingZone. Bookworm Deluxe, PC Download, Full Game, For PC. INFO: It is Full and Complete Game 100% Working.

Taher Al-Sahhaf

Department of Chemical Engineering, College of Engineering and Petroleum, Kuwait Univerity, Safat, Kuwait

Amal Elkilani

Department of Chemical Engineering, College of Engineering and Petroleum, Kuwait Univerity, Safat, Kuwait

Ratings and Reviews

Fundamentals of Petroleum Refining presents the fundamentals of thermodynamics and kinetics, and it explains the scientific background essential for understanding refinery operations. The text also provides a detailed introduction to refinery engineering topics, ranging from the basic principles and unit operations to overall refinery economics.The book covers important topics, such as clean fuels, gasification, biofuels, and environmental impact of refining, which are not commonly discussed in most refinery textbooks. Throughout the source, problem sets and examples are given to help the reader practice and apply the fundamental principles of refining. Chapters 1-10 can be used as core materials for teaching undergraduate courses. The first two chapters present an introduction to the petroleum refining industry and then focus on feedstocks and products. Thermophysical properties of crude oils and petroleum fractions, including processes of atmospheric and vacuum distillations, are discussed in Chapters 3 and 4. Conversion processes, product blending, and alkylation are covered in chapters 5-10. The remaining chapters discuss hydrogen production, clean fuel production, refining economics and safety, acid gas treatment and removal, and methods for environmental and effluent treatments.

This source can serve both professionals and students (on undergraduate and graduate levels) of Chemical and Petroleum Engineering, Chemistry, and Chemical Technology. Beginners in the engineering field, specifically in the oil and gas industry, may also find this book invaluable.

'>

'>